AUTOMATIC E-BABY CRADLE SWING BASED ON BABY CRY.

My latest Arduino DIY project is Automatic

E-Baby Cradle Swing based on Baby Cry.

Parents in the present world are busy in their professional

life, so they do not get sufficient time to take care of their babies. It may

be expensive for the household to afford a nanny.

Today’s woman has to manage home along with their office

work simultaneously. After long working hours, they have to take care of the

home along with the baby. They may not get enough time to swing the cradle

manually and sooth the baby. Moreover, in today’s life style, it is very difficult

even for the housewives to sit nearby their infants and sooth them whenever

they cry. Enhancing sleep quality is an important research topic, as quality

sleep is important for everyone, especially for infants . A comfortable

electric cradle with a low power consumption that can letinfants fall asleep

quickly is desired by many parents and numerous novel inventions based on swing

mechanisms in the form of springs or rods have been developed .Hospitals have

neonatal and maternity units. Nurses in these units have to take care of baby

and sooth them whenever they cry.

The system is designed to help parents and nurses in infants

care. The design aims at following points:

1.

Cradle starts swinging automatically when baby

cry and swings till the baby stops crying.

Sends message to mother’s mobile when

baby cries for more than a stipulated time indicating that baby needs

attention.

HARDWARE EXPLANATION:-

GSM module

Audio sensor KY-038

SERVO MOTOR

Arduino uno

Cradle (model)

Resistors

capacitors

MORE IMAGES

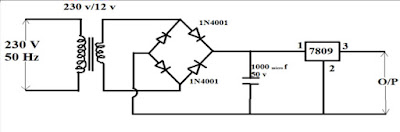

POWER SUPPLY DESIGN

use;Arduino uno

Arduino ide; http://www.arduino.org/downloads

Arduino coding handled by :- PRANAV S NAIR (pranavsnair93@gmail.com)

Project helping courtesy:- Felix philip <felixphilip86@gmail.com>

Project helping courtesy:- Felix philip <felixphilip86@gmail.com>

CODE

#include <Servo.h>

#include <SoftwareSerial.h>

SoftwareSerial mySerial(9, 10);

int sensorPin = A0; // select the input pin for the potentiometer // select the pin for the LED

int sensorValue = 0;

int count=0;// variable to store the value coming from the sensor

int motor=8;

int motor2=10;

void setup ()

{

Serial.begin (9600);

mySerial.begin(9600); // Setting the baud rate of GSM Module // Setting the baud rate of Serial Monitor (Arduino)

delay(100);

pinMode(motor,OUTPUT);

pinMode(motor2,OUTPUT);

}

void loop ()

{ delay(200);

sensorValue = analogRead (sensorPin);

Serial.println (sensorValue, DEC);

if(sensorValue > 65)

{ digitalWrite(motor2,LOW);

digitalWrite(motor,HIGH);

delay(400);

digitalWrite(motor,LOW);

digitalWrite(motor2,HIGH);

delay(400);

}

else

{

digitalWrite(motor2,LOW);

digitalWrite(motor,LOW);

}

if(count>5)

{

if (Serial.available()>0)

switch(Serial.read())

{

case 's':

SendMessage();

break;

case 'r':

RecieveMessage();

break;

}

if (mySerial.available()>0)

Serial.write(mySerial.read());

}

}

void SendMessage()

{

mySerial.println("AT+CMGF=1"); //Sets the GSM Module in Text Mode

delay(1000); // Delay of 1000 milli seconds or 1 second

mySerial.println("AT+CMGS=\"+919995856777\"\r"); // Replace x with mobile number

delay(1000);

mySerial.println("baby is crying..!");// The SMS text you want to send

delay(100);

mySerial.println((char)26);// ASCII code of CTRL+Z

delay(1000);

}

void RecieveMessage()

{

mySerial.println("AT+CNMI=2,2,0,0,0"); // AT Command to receive a live SMS

delay(1000);

}